Innovation in the paper coating industry■

- Greater efficiency

- Fewer semi-finished product losses

- Energy-saving solutions

- Unique solutions

- Production quality

- Competitive implementation cost

The line is intended for chemical coating and polymerization of paper used in various industries and purposes. Unlike commonly used paper bathing technologies, our solution uses innovative spraying and blowing technology. In order to reduce energy consumption and ensure production safety, we abandoned the use of a conventional furnace in favour of IR radiators.

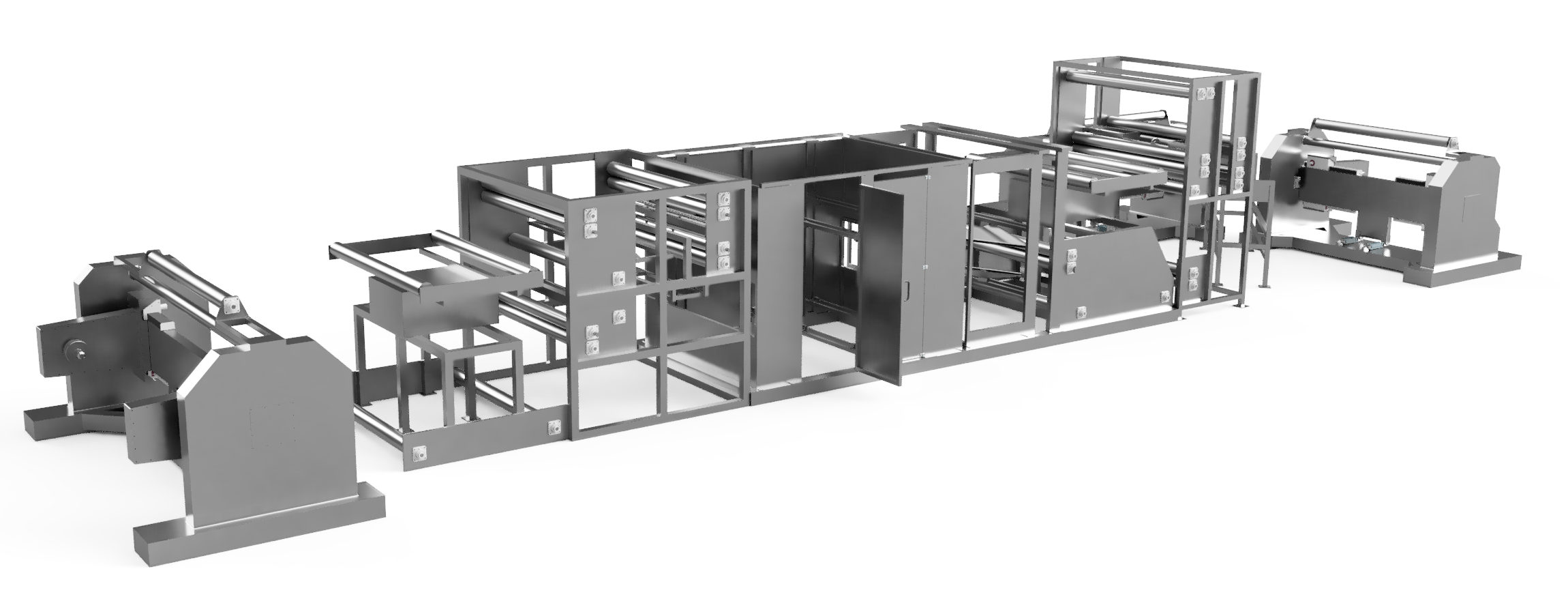

Principle of operation of the FPLline

Our technological line, compared to conventional technologies, enables more effective application of the film to paper and its subsequent polymerization.

The process begins with the unwinding and centring section of the paper web. The next step in the process is to apply chemical material to the paper on both sides using dedicated spray nozzles. In order to activate the applied chemical, the paper is introduced into an IR oven which heats the product to the activation temperature, leading to polymerization of the active ingredients of the chemical preparation. The next section is the paper cooling system, where the product temperature will be reduced below 40°C. The final stage is cutting the paper ribbon longitudinally to obtain two adjustable ribbon widths (optional). The obtained ribbons are wound onto new bales by two independent winding stations.

The mechanical system is equipped with systems for positioning the paper web and preparing industrial chemicals with a cascade solution mixing system and material recirculation.

The essence of the solution is spray coating, which is an innovative solution in the paper industry. The use of spray nozzles allows for better control of coating application parameters. Thanks to this solution, a laminar surface of the final product is obtained.

The line is equipped with a safety system integrated with the control system, which ensures a high level of operational safety.

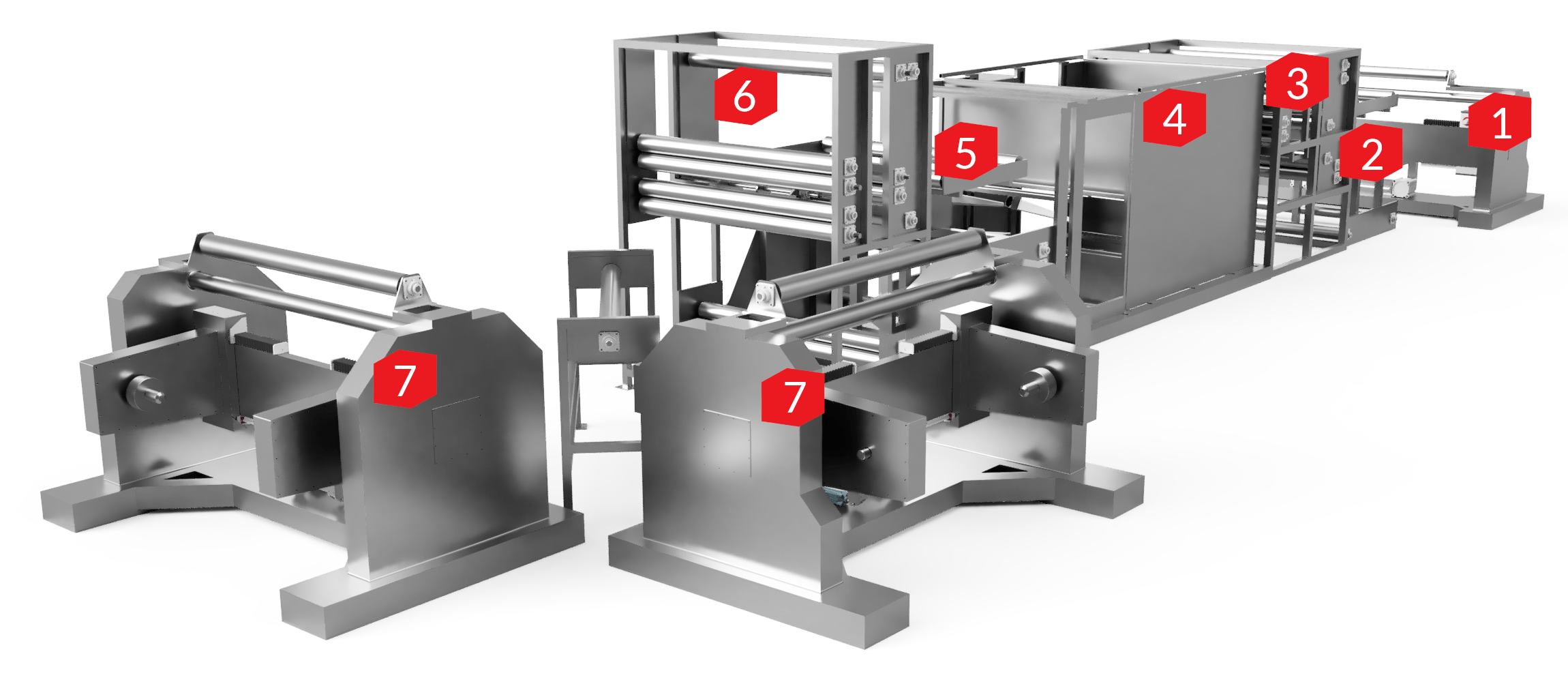

There are several sections on the line, each of which has a specific task in the process. The sections are as follows:

1

Unwinding machine

2

Web-guiding systems

3

Spraying and blowing system

4

IR furnace

5

Cooling and guiding section

6

Longitudinal cutting and final guidance section

7

Winding machines

FPLLine parameters

- Performance: 250 m/min

- Max. diameter of the roll: 1 250 mm

- Max. width of the roll: 2 000 mm

- Max. weight of the roll: 2 500 kg

- Coating: Double-sided, contactless by spraying and blowing

- Polymerization: By IR radiation

- IR oven temperature: max 160°C

- Cooling: Blowing cold air over the heat exchanger

English

English  Polski

Polski Deutsch

Deutsch